The Science of Premium Sound Using Miniature Transducers

The performance and versatility of balanced armature drivers enables premium sound in highly miniaturized devices, from sophisticated digital hearing aids to wearable-computing systems

Knowles Corporation developed balanced armature drivers 60 years ago originally for use in hearing-health devices and later for earphones. This advancement enabled the design of compact, comfortable, high-quality hearing-health devices that could be worn all day and operated with small batteries—the same demands that are now placed on in-ear wearable devices. This paper will describe the construction of a balanced armature driver, discuss the volume requirements for vented and unvented balanced armature drivers as compared to small dynamic speakers, and analyze the driver power requirements with both standard and class-D amplifiers. Knowles offers many lines of balanced armature components, but this discussion will focus on a comparison of the benefits and performance of its RAB Series versus a 6mm dynamic speaker.

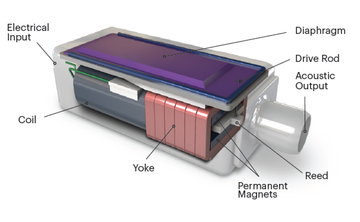

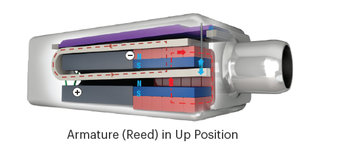

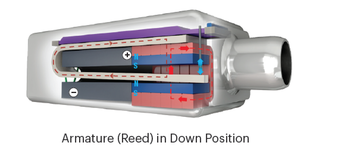

Construction of a Balanced Armature Driver

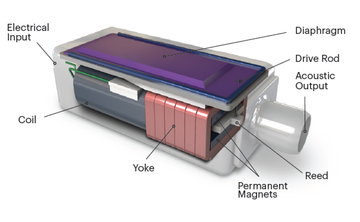

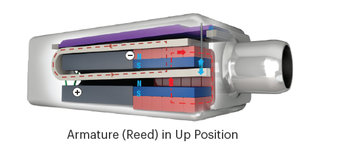

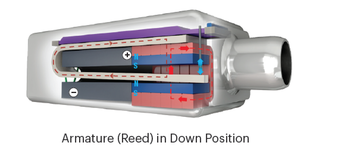

Balanced armature drivers are capable of reliably reproducing high-fidelity sound in an exceptionally small size because they incorporate a specially constructed reed that is highly magnetically permeable, specially annealed and placed precisely in the center between the magnets. The alternating current (AC) signal in the static coil creates a magnetic flux in the reed. This creates an imbalance in the reed and cause AC motion at the tip, transferred through a coupling rod to a lightweight and very stiff aluminum diaphragm. The diaphragm is free of resonances in the audio band, producing excellent clarity.

The coil moves in a dynamic speaker, while it is stationary in the balanced armature driver. This means that much more copper can be used in the balanced armature coil, leading to a reduction in restrictive losses. The coupling of the magnetic circuit is also stronger in the balanced armature driver. The magnetic surface area is larger, creating a larger driving field. The end result is higher output for a given size. Also, the larger mass of the dynamic speaker’s moving parts (diaphragm + coil) makes it harder to efficiently reproduce high frequencies as compared to balanced armature drivers with their thin and light diaphragm and stationary coil.

Balanced Armature Driver and Dynamic Speaker Volume Requirements

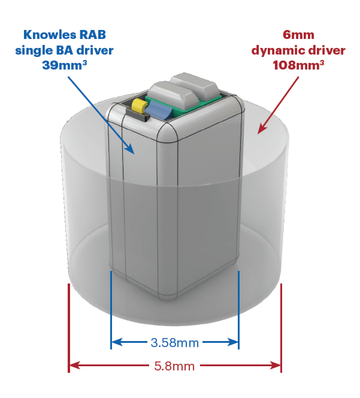

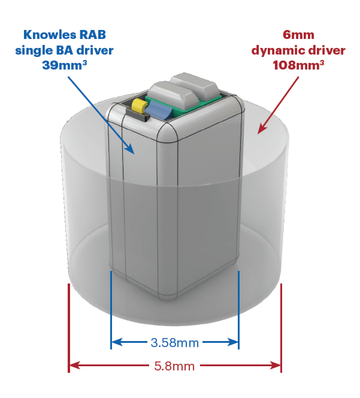

If the size of an earphone or in-ear wearable device is too large, the user might find it uncomfortable after long use. Just as with modern hearing-health devices intended for all-day wear (many of which place the driver directly in the ear canal), a driver of smaller volume in an in-ear wearable device translates to smaller overall device size and thus to real improvement in fit and comfort. Based on driver volume alone, the RAB balanced armature driver will be only about 1/3 the size of a 6mm dynamic speaker. This leaves more room for the accompanying electronics, sensors and battery.

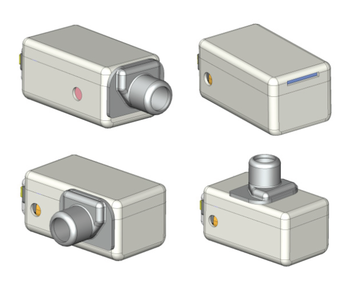

Also to be considered is the requirement for back volume in both cases. Dynamic speakers typically require a substantial back volume to achieve the optimum frequency response. One option is to provide a vent in the housing to the open air, though this may not be preferred for devices meant for outdoor use in all weather. The other option is to provide the back volume within the enclosure. A typical back volume for a 6mm dynamic speaker would be about the same as the driver volume itself, or roughly 100 mm3. In contrast, one can use an unvented balanced armature driver that requires no external back volume at all. Unvented drivers provide a balanced acoustic signature especially suitable for voice applications as well as music. When the designer wishes to provide elevated bass, a vented balanced armature driver is called for. The typical rule of thumb for back volume is to provide minimum 50% of the exterior volume of the driver – substantially less than is required for the dynamic speaker. Using the RAB Series as an example, the typical back volume would be 20mm3. One other factor when considering volumetric efficiency is the form factor of the round dynamic speaker vs. the rectangular balanced armature. Overall volumetric efficiency can be improved when using a balanced armature driver because other components (such as the chipset or Bluetooth transceiver) are more easily packed tightly around it. Additional design flexibility is available because the sound-port opening on a balanced armature driver can be placed on several surfaces – edge, side, or top – with or without tube.

Overall Volume Requirement

Balanced Armature Series (RAB) vs. 6mm Dynamic Speaker

-vs-6mm-dynamic-speaker.png?sfvrsn=a5fe74b1_0)

Comparing Balanced Armature and Dynamic Efficiency

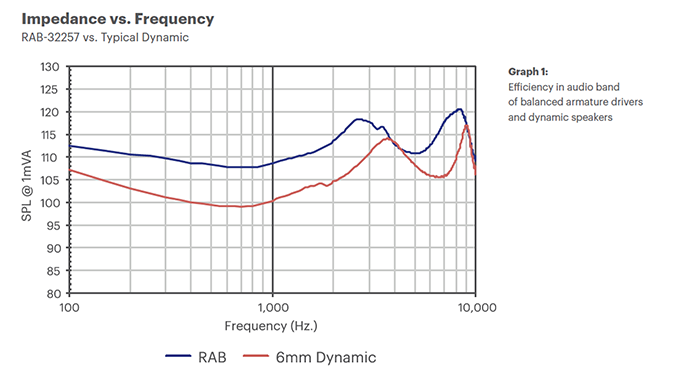

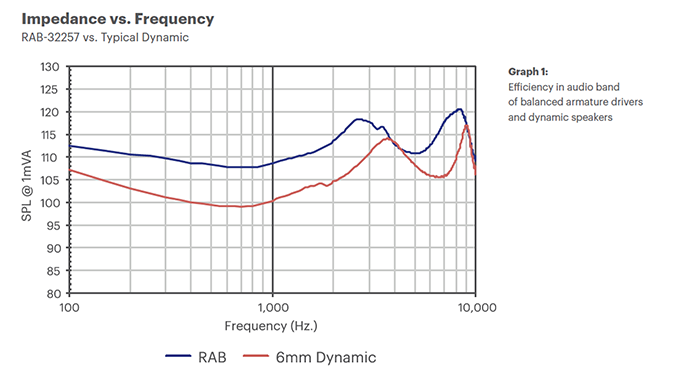

One way to measure the efficiency of a transducer is to measure the sound pressure created in a 2cc test chamber for a fixed level of Volt•Amps. (Graph 1). Measurements of sound pressure instead of acoustic output power were recorded because the test chamber does not actually absorb any power, meaning that it is not possible to measure the power being delivered by the transducer. The unit of measurement used is Volt•Amps rather than Watts as the phase angle between voltage and current often has little impact to the total power dissipation of the battery, amplifier, and transducer.

In efficiency measurements, every three decibels (dB) represents a doubling of power consumption. Therefore the results of the side-by-side tests shown in Graph 1 reveal that a dynamic speaker consumed six times more power than the RAB driver in a frequency range from 2 kHz to 300 Hz. In real-world terms, this means that if the transducer was the dominant consumer of power in a music system, a battery charge that lasts a week in a listening device driven by balanced armature driver technology would last little more than a day in a dynamic speaker. In in-ear wearables the total power savings resulting from the use of balanced armature drivers is of course dependent on the chipset power consumption in various operating modes. As chipset power efficiency improves, the audio transducer power consumption assumes more importance.

Balanced Armature Driver Efficiency in a Class-D System

Class-D switching amplifiers are increasingly seen as a viable option to overcome size constraints and excessive power consumption. At the most common switching frequencies a balanced armature driver can offer substantial power savings. Additionally, when used in conjunction with a class-D amplifier, the balanced armature driver does not need an external inductor to achieve high efficiency. This is not true of dynamic speakers where the designer must choose between efficiency and added component size and cost. This type of setup is already widely used where size and power are critical factors, such as in hearing aids, automotive, and professional sound systems. In wireless earphones and in-ear wearable devices the use of Class-D systems is likely to increase as the need for reducing size and power accelerates.

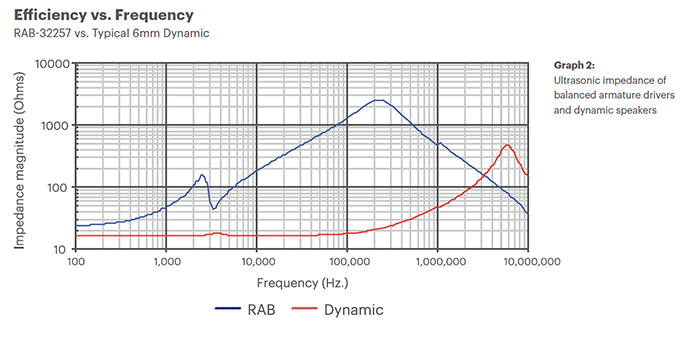

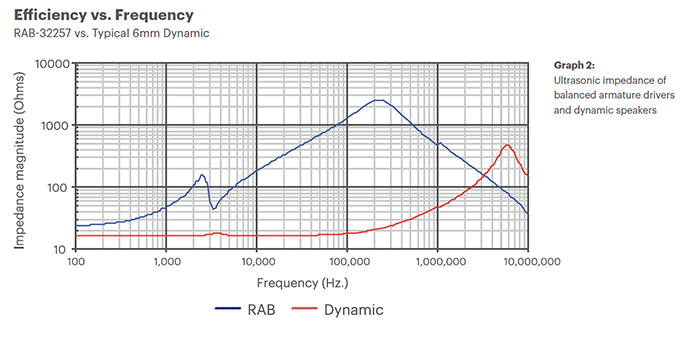

The substantial efficiency gains with Class-D amplifiers stem from the different impedance characteristics of balanced armature drivers vs. dynamic speakers (Graph 2). The balanced armature driver works especially well with a switching amplifier due to its high impedance at ultrasonic frequencies. By their method of operation, class-D amplifiers produce significant energy at ultrasonic frequencies. This produced energy needs to be blocked by an inductive filter in order to achieve higher efficiency. The inherent inductance of balanced armature drivers at ultrasonic frequencies acts as a natural energy-saving filter for the amplifier. On the other hand, systems with dynamic speakers must find a balance between the effects of higher power loss and the added size and cost of a large inductive filter. Dynamic speakers are predominantly resistive throughout the audio band and up to a decade above the audio band. Above this frequency the inductance of the voice coil causes the impedance to climb. At very high frequencies, the parasitic capacitance in the voice coil and the cabling cause the impedance to fall.

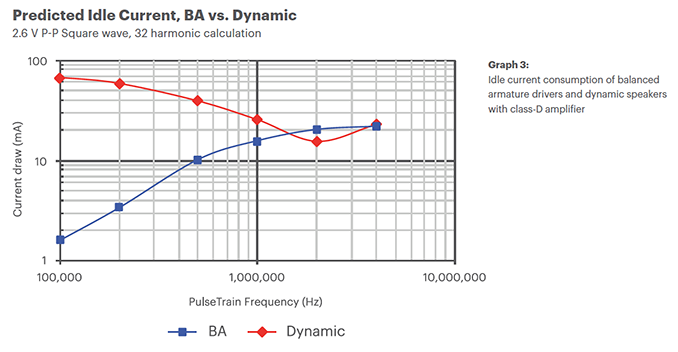

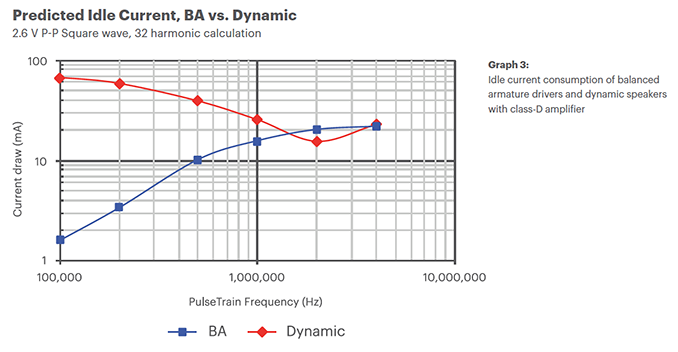

The efficient magnetic coupling of balanced armature drivers is responsible for their high inductance. Their transition from being resistive to inductive happens at much lower audio frequencies than dynamic drivers, typically around 100 to 300 Hz. This characteristic makes the impedance of the balanced armature driver 100 times greater than a dynamic speaker near the 100-kHz range. This allows the balanced armature driver to naturally reject the ultrasonic output of the class-D amplifier. The device under test in Graph 2 has a peak at about 200 kHz. Above this frequency parasitic capacitance begins to take over. Extended bandwidth balanced armature drivers are available where the impedance peak can be at frequencies as high as 2 MHz. Even when no audio signal is present, the idling signal from a class-D amplifier will constantly deliver significant power to the speaker if the impedance is not high enough. A class-D amplifier modulates the duty cycle of a rail-to-rail square wave. When there is no audio signal, the duty cycle is near 50%. Therefore, a square wave can be used to calculate the idle current of a class-D amplifier, applying the impedance curves shown above. Class-D amplifiers can be operated with a wide range of switching frequencies. Large amplifiers tend to use lower switching frequencies, near 100 kHz, while the very small amplifiers used in hearing aids use switching frequencies as high as 3 MHz. Amplifiers for earphones and wearables tend to fall in an intermediate range of about 400 to 800kHz.

Graph 3 shows the predicted idle-current vs. switching frequency for the dynamic speaker and balanced armature driver shown in Graph 2. At the lowest switching frequencies, the idle current from a dynamic speaker would exceed the current used by audio signals! In contrast, the balanced armature current is 40 times smaller. The idle current in a dynamic speaker at the typical switching frequency of 400 kHz is five times higher than for a balanced armature driver.

The higher audio efficiency of balance armature drivers allows the user to choose a higher impedance transducer, which in turn improves the efficiency of the electronics. As we showed before, the efficiency of the RAB driver is six times higher than an equivalent dynamic speaker. Therefore, one can use six times higher impedance and still get the same amount of sound output. The higher impedance in turn reduces the audio-related current through the battery and amplifier output transistors by a factor of six, proportionately reducing the heating losses in these components.

Conclusion

Today’s advanced in-ear wearable devices require small size, light weight, and long battery life in addition to providing a quality audio experience. Knowles balanced armature drivers provide a unique combination of excellent audio quality, low total volumetric requirements, and significant power savings, both with normal drive and especially with Class-D amplifiers. As the power consumption of chipsets is reduced under various use cases, the power savings obtained by using balanced armature drivers will become even more significant.

This white paper is also available as a PDF download. For further information, please visit the Balanced Armature Education Center.

About the Authors:

Tom Miller is the Senior Principal Engineer for Knowles Corporation. He can be reached at 630-285-5882 or at Tom.Miller@Knowles.com.

Andrew Bellavia is the Director of Market Development, Specialty Components-Acoustics for Knowles Corporation. He can be reached at 630-250-5194 or at Andrew.Bellavia@Knowles.com. Knowles is a market leader and global supplier of advanced micro-acoustic solutions and specialty components serving the mobile communications, consumer electronics, medical technology, military, aerospace and industrial markets. Knowles has a leading position in micro-electro-mechanical systems microphones, speakers and receivers which are used in smartphones, tablets and mobile handsets. Knowles is also a leading manufacturer of transducers used in hearing aids and other medical devices and has a strong position in oscillators (timing devices) and capacitor components which enable various types of communication. Knowles’ focus on the customer, combined with unique technology, rigorous testing and global scale, helps to deliver innovative solutions and consistently dependable and precise products. Founded in 1946 and headquartered in Itasca, Illinois, Knowles has more than 10,000 employees in 36 locations around the world. For more information, visit www.knowles.com.

Knowles Corporation developed balanced armature drivers 60 years ago originally for use in hearing-health devices and later for earphones. This advancement enabled the design of compact, comfortable, high-quality hearing-health devices that could be worn all day and operated with small batteries—the same demands that are now placed on in-ear wearable devices. This paper will describe the construction of a balanced armature driver, discuss the volume requirements for vented and unvented balanced armature drivers as compared to small dynamic speakers, and analyze the driver power requirements with both standard and class-D amplifiers. Knowles offers many lines of balanced armature components, but this discussion will focus on a comparison of the benefits and performance of its RAB Series versus a 6mm dynamic speaker.

Construction of a Balanced Armature Driver

Balanced armature drivers are capable of reliably reproducing high-fidelity sound in an exceptionally small size because they incorporate a specially constructed reed that is highly magnetically permeable, specially annealed and placed precisely in the center between the magnets. The alternating current (AC) signal in the static coil creates a magnetic flux in the reed. This creates an imbalance in the reed and cause AC motion at the tip, transferred through a coupling rod to a lightweight and very stiff aluminum diaphragm. The diaphragm is free of resonances in the audio band, producing excellent clarity.

The coil moves in a dynamic speaker, while it is stationary in the balanced armature driver. This means that much more copper can be used in the balanced armature coil, leading to a reduction in restrictive losses. The coupling of the magnetic circuit is also stronger in the balanced armature driver. The magnetic surface area is larger, creating a larger driving field. The end result is higher output for a given size. Also, the larger mass of the dynamic speaker’s moving parts (diaphragm + coil) makes it harder to efficiently reproduce high frequencies as compared to balanced armature drivers with their thin and light diaphragm and stationary coil.

Balanced Armature Driver and Dynamic Speaker Volume Requirements

If the size of an earphone or in-ear wearable device is too large, the user might find it uncomfortable after long use. Just as with modern hearing-health devices intended for all-day wear (many of which place the driver directly in the ear canal), a driver of smaller volume in an in-ear wearable device translates to smaller overall device size and thus to real improvement in fit and comfort. Based on driver volume alone, the RAB balanced armature driver will be only about 1/3 the size of a 6mm dynamic speaker. This leaves more room for the accompanying electronics, sensors and battery.

Also to be considered is the requirement for back volume in both cases. Dynamic speakers typically require a substantial back volume to achieve the optimum frequency response. One option is to provide a vent in the housing to the open air, though this may not be preferred for devices meant for outdoor use in all weather. The other option is to provide the back volume within the enclosure. A typical back volume for a 6mm dynamic speaker would be about the same as the driver volume itself, or roughly 100 mm3. In contrast, one can use an unvented balanced armature driver that requires no external back volume at all. Unvented drivers provide a balanced acoustic signature especially suitable for voice applications as well as music. When the designer wishes to provide elevated bass, a vented balanced armature driver is called for. The typical rule of thumb for back volume is to provide minimum 50% of the exterior volume of the driver – substantially less than is required for the dynamic speaker. Using the RAB Series as an example, the typical back volume would be 20mm3. One other factor when considering volumetric efficiency is the form factor of the round dynamic speaker vs. the rectangular balanced armature. Overall volumetric efficiency can be improved when using a balanced armature driver because other components (such as the chipset or Bluetooth transceiver) are more easily packed tightly around it. Additional design flexibility is available because the sound-port opening on a balanced armature driver can be placed on several surfaces – edge, side, or top – with or without tube.

Overall Volume Requirement

Balanced Armature Series (RAB) vs. 6mm Dynamic Speaker

-vs-6mm-dynamic-speaker.png?sfvrsn=a5fe74b1_0)

Comparing Balanced Armature and Dynamic Efficiency

One way to measure the efficiency of a transducer is to measure the sound pressure created in a 2cc test chamber for a fixed level of Volt•Amps. (Graph 1). Measurements of sound pressure instead of acoustic output power were recorded because the test chamber does not actually absorb any power, meaning that it is not possible to measure the power being delivered by the transducer. The unit of measurement used is Volt•Amps rather than Watts as the phase angle between voltage and current often has little impact to the total power dissipation of the battery, amplifier, and transducer.

In efficiency measurements, every three decibels (dB) represents a doubling of power consumption. Therefore the results of the side-by-side tests shown in Graph 1 reveal that a dynamic speaker consumed six times more power than the RAB driver in a frequency range from 2 kHz to 300 Hz. In real-world terms, this means that if the transducer was the dominant consumer of power in a music system, a battery charge that lasts a week in a listening device driven by balanced armature driver technology would last little more than a day in a dynamic speaker. In in-ear wearables the total power savings resulting from the use of balanced armature drivers is of course dependent on the chipset power consumption in various operating modes. As chipset power efficiency improves, the audio transducer power consumption assumes more importance.

Balanced Armature Driver Efficiency in a Class-D System

Class-D switching amplifiers are increasingly seen as a viable option to overcome size constraints and excessive power consumption. At the most common switching frequencies a balanced armature driver can offer substantial power savings. Additionally, when used in conjunction with a class-D amplifier, the balanced armature driver does not need an external inductor to achieve high efficiency. This is not true of dynamic speakers where the designer must choose between efficiency and added component size and cost. This type of setup is already widely used where size and power are critical factors, such as in hearing aids, automotive, and professional sound systems. In wireless earphones and in-ear wearable devices the use of Class-D systems is likely to increase as the need for reducing size and power accelerates.

The substantial efficiency gains with Class-D amplifiers stem from the different impedance characteristics of balanced armature drivers vs. dynamic speakers (Graph 2). The balanced armature driver works especially well with a switching amplifier due to its high impedance at ultrasonic frequencies. By their method of operation, class-D amplifiers produce significant energy at ultrasonic frequencies. This produced energy needs to be blocked by an inductive filter in order to achieve higher efficiency. The inherent inductance of balanced armature drivers at ultrasonic frequencies acts as a natural energy-saving filter for the amplifier. On the other hand, systems with dynamic speakers must find a balance between the effects of higher power loss and the added size and cost of a large inductive filter. Dynamic speakers are predominantly resistive throughout the audio band and up to a decade above the audio band. Above this frequency the inductance of the voice coil causes the impedance to climb. At very high frequencies, the parasitic capacitance in the voice coil and the cabling cause the impedance to fall.

The efficient magnetic coupling of balanced armature drivers is responsible for their high inductance. Their transition from being resistive to inductive happens at much lower audio frequencies than dynamic drivers, typically around 100 to 300 Hz. This characteristic makes the impedance of the balanced armature driver 100 times greater than a dynamic speaker near the 100-kHz range. This allows the balanced armature driver to naturally reject the ultrasonic output of the class-D amplifier. The device under test in Graph 2 has a peak at about 200 kHz. Above this frequency parasitic capacitance begins to take over. Extended bandwidth balanced armature drivers are available where the impedance peak can be at frequencies as high as 2 MHz. Even when no audio signal is present, the idling signal from a class-D amplifier will constantly deliver significant power to the speaker if the impedance is not high enough. A class-D amplifier modulates the duty cycle of a rail-to-rail square wave. When there is no audio signal, the duty cycle is near 50%. Therefore, a square wave can be used to calculate the idle current of a class-D amplifier, applying the impedance curves shown above. Class-D amplifiers can be operated with a wide range of switching frequencies. Large amplifiers tend to use lower switching frequencies, near 100 kHz, while the very small amplifiers used in hearing aids use switching frequencies as high as 3 MHz. Amplifiers for earphones and wearables tend to fall in an intermediate range of about 400 to 800kHz.

Graph 3 shows the predicted idle-current vs. switching frequency for the dynamic speaker and balanced armature driver shown in Graph 2. At the lowest switching frequencies, the idle current from a dynamic speaker would exceed the current used by audio signals! In contrast, the balanced armature current is 40 times smaller. The idle current in a dynamic speaker at the typical switching frequency of 400 kHz is five times higher than for a balanced armature driver.

The higher audio efficiency of balance armature drivers allows the user to choose a higher impedance transducer, which in turn improves the efficiency of the electronics. As we showed before, the efficiency of the RAB driver is six times higher than an equivalent dynamic speaker. Therefore, one can use six times higher impedance and still get the same amount of sound output. The higher impedance in turn reduces the audio-related current through the battery and amplifier output transistors by a factor of six, proportionately reducing the heating losses in these components.

Conclusion

Today’s advanced in-ear wearable devices require small size, light weight, and long battery life in addition to providing a quality audio experience. Knowles balanced armature drivers provide a unique combination of excellent audio quality, low total volumetric requirements, and significant power savings, both with normal drive and especially with Class-D amplifiers. As the power consumption of chipsets is reduced under various use cases, the power savings obtained by using balanced armature drivers will become even more significant.

This white paper is also available as a PDF download. For further information, please visit the Balanced Armature Education Center.

About the Authors:

Tom Miller is the Senior Principal Engineer for Knowles Corporation. He can be reached at 630-285-5882 or at Tom.Miller@Knowles.com.

Andrew Bellavia is the Director of Market Development, Specialty Components-Acoustics for Knowles Corporation. He can be reached at 630-250-5194 or at Andrew.Bellavia@Knowles.com. Knowles is a market leader and global supplier of advanced micro-acoustic solutions and specialty components serving the mobile communications, consumer electronics, medical technology, military, aerospace and industrial markets. Knowles has a leading position in micro-electro-mechanical systems microphones, speakers and receivers which are used in smartphones, tablets and mobile handsets. Knowles is also a leading manufacturer of transducers used in hearing aids and other medical devices and has a strong position in oscillators (timing devices) and capacitor components which enable various types of communication. Knowles’ focus on the customer, combined with unique technology, rigorous testing and global scale, helps to deliver innovative solutions and consistently dependable and precise products. Founded in 1946 and headquartered in Itasca, Illinois, Knowles has more than 10,000 employees in 36 locations around the world. For more information, visit www.knowles.com.